High Quality by Reis

Customer Service by Reis Robotics

Successful pillars of sustainable Customer Service.

And from A to Z.

Service. Expertise. Individuality.

Quality terms for our objective: customer satisfaction made to measure.

The economic requirements for success in the market are problem-free production, planning reliability, and of course quality assurance. As an expert services partner, Reis Robotics provides you with customized concepts for your automation system.

Exact, value-efficient and just in time.

And by the way, we work independently of manufacturer and all over the world!

Expertise for Diversity.

Just Our Thing.

Reis Robotics offers you a smart service and maintenance management concept, systematically tailored to your requirements. From individual elements such as robots, presses and their peripherals, to complex overall systems.

Diversity is at the heart of what we do. Why? Because no two systems are the same and objectives are shaped by what we call quality thinking.

Individuality by Reis Robotics – that is precision quality based on certified processes with traceable facts for process reliability, where these are required. In print and digital form.

And by the way, we also conduct DGUV safety inspections.

Qualification in focus.

Secure the ideal conditions for a personal upgrade for your employees.

Qualification is the key to effective employees. Some people call them the industry’s capital, but we call them the heartbeat. Why? Because perfect automation always rests on the abilities of the people operating the system. The ideal way of securing these success stories for the long term is via the Reis Robotics training center, with its exactly tailored training programs.

‘With an ideal mix of theory and practice, we create the perfect knowledge base for the qualification of your employees.’

Special knowledge for complexity.

We develop precisely targeted training events to meet your individual requirements.

Within our modular training concepts, the focus is on the gradual development of the participants. The topics covered here are both software-supported programming and the safe operation of automation systems. With seminars based accurately on the training objective, you profit from our practical modules that cover the individual requirements of your employees alongside the principles of robotic systems.

Our program is intended for system operators and setters as well as for service technicians and system programmers.

Safe is safe!

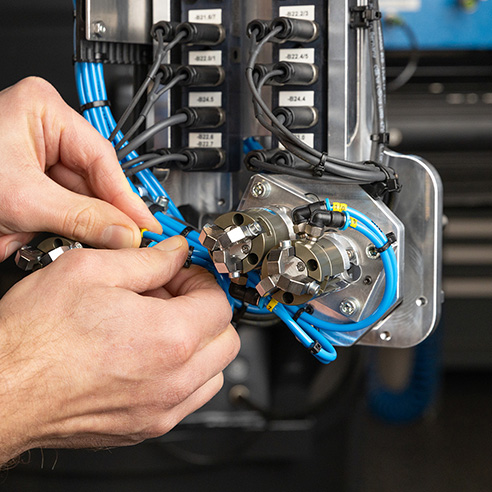

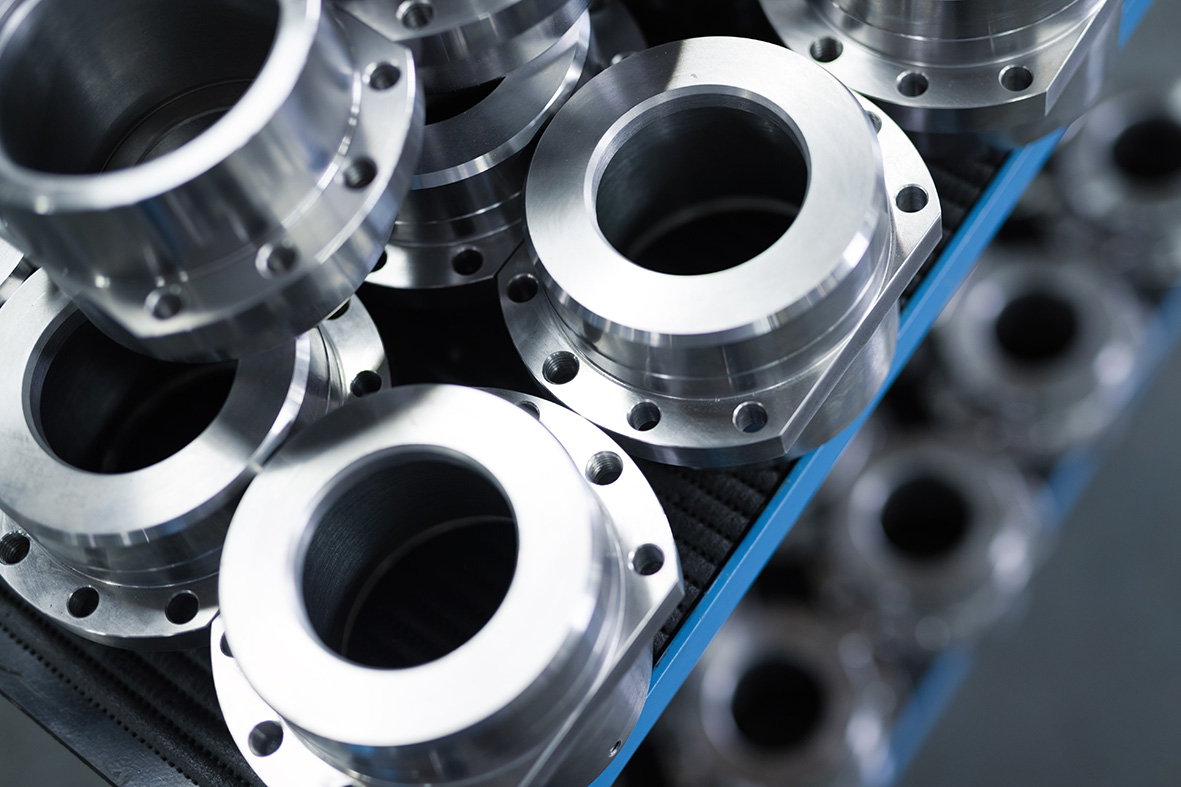

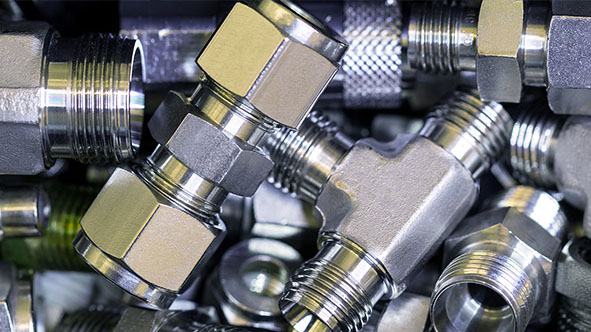

With Reis Robotics’ precision parts portfolio, you secure ongoing viability for tomorrow from today.

Downtimes caused by wear and repairs are a complex topic and a significant factor when it comes to long-term economic viability. Minimizing these times is the core task of our spare parts management division. Here, all our attention is directed to the exact suitability and availability of the right components, and all of it just in time.

High-performance components for economic effectiveness.

Plug and Play.

All in one.

Spare parts packages provide the perfect system portfolio for current consumable and wear parts. Compiled individually for you with the experience of a high-performance service management division.

One for All.

Our spare parts packages offer you economical all-in-one solutions, individually configured to your production requirements. From bundles of spare, reserve or wear parts through to specific parts packages that ensure that you have the complete range of essential parts when you need it.

Secure your productivity.

Sustainability as the optimization of operational efficiency and ecological footprint.

Automation systems are subject to an intensive performance cycle. The older a system becomes, the more prone it is to faults and the less profitable it becomes. Apart from increasing repair and maintenance costs, older systems do not offer the extended diagnosis, analysis, safety, and networking functions that are required today.

Whether you are seeking a conversion or modernization of components and/or control or information systems, we will work with you to plan a coherent modernization concept and will execute it with the renowned Reis quality. From the evaluation of existing components to the development of a modernization concept and through to the complete rebuild. And of course, we will comply with the downtimes envisaged.

Update

‘An eye to the future. With a quality update to your automation system assuring long-term performance capacity for your production.’

Making new out of old is the art of sustainability.

Admittedly, a complete system modernization like the example shown here calls for high levels of competence, motivation, and experience. Attributes that the experts in our modernization team display on a daily basis. Real sustainability with substance.

Do you have questions?

Our experts are there and ready to advise you.

Do you already know our new service catalog?

Reis is a company of

Aretè Cocchi Technology is an industrial group devoted to innovation, technology and growth. Established in the 90s by Gino Cocchi, today ACT consists of 14 companies that employ more than 850 people worldwide, representing more than 30 nationalities. Manufacturing in Italy, France, Germany, the U.S., Switzerland and China; commercial and technical centers in more than 15 countries; and sales in over 100 countries.